Val worked for a German electronics company that produced most of their hardware in an Eastern European plant. German wasn’t spoken there, but the plant employed translators to bridge the communication gap.

The first test units of Val’s major new product were about to hit production. His head engineer, Schwierigkeitmacher, would be visiting to the plant to ensure everything was in order.

“Make sure they know to take extra care of the FET,” Val cautioned, naming a type of transistor they’d had problems with before.

“No problem- I planned to remind them,” Schwierigkeitmacher said.

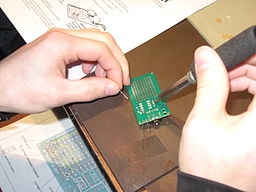

Production proceeded on schedule, and the units arrived in Germany. Testing looked good at first. Within a few days, though, most of the units had malfunctioned. Val’s team opened up the failed units and found signs of heavy corrosion on the circuit boards, like someone had sprinkled each one with acid.

Confused, Val contacted the product supervisor at the plant. A translator jumped on to facilitate the call.

“We assembled everything according to spec,” the supervisor insisted via the translator. “We even followed Herr Schwierigkeitmacher’s special instructions regarding the Fett.”

“But everything on the board is fried, across multiple units,” Val replied. “Something has gone wrong.”

“Well, das Fett is corrosive, sir,” the supervisor/translator reminded, “but Herr Schwierigkeitmacher specifically asked for it. The last time we gainsaid any of your instructions, it caused a lot of trouble. Therefore-”

“Wait wait wait.” Val gaped. “You’re referring to F-E-T-T as in fat, grease?”

“Jawohl, yes. Flux grease- that’s the only type we work with here.”

Val put down the telephone receiver for a moment to facilitate a proper facepalm. He picked it back up and explained, “Schwierigkeitmacher was referring to the FET transistor. F-E-T. The only FET that makes sense to go on this circuit board! Didn’t the translator know what that was?”

“All translators have excellent technical fluency,” the translator said.

“Apparently not!” Val cried.

“How are we to know every single component you might ask us to work with?”

She had a point, but Val still had a defective test batch on his hands and no acknowledgement of fault. Several more telephone exchanges and management escalations later, Val was assured the problem will be fixed for the next test run. In the meantime, Val instructed his peers to thoroughly explain any technical terms they might use when conferring directions to the plant.

Life went on- but on Val’s next project, another mistranslation caused dozens of people to search in vain for a mysterious “diode number ten.” Someone hadn’t thought it necessary to explain what a Zener diode was (zehn = ten in German).